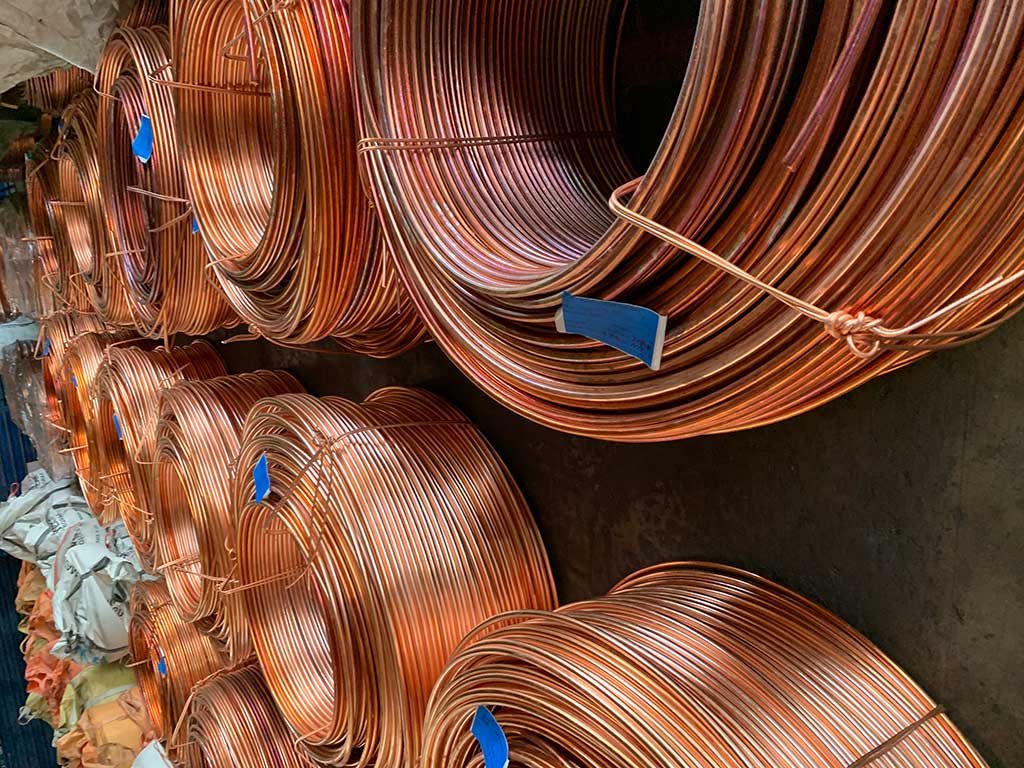

At TA WIN, we produce Oxygen Free High Thermal Conductivity Copper Rod (OFHC)

Via direct conversion of LME Grade “A” copper cathodes. Our UPCAST® Plant Casts (Furnace/Melter) the copper under carefully controlled conditions to prevent contamination of the pure oxygen free copper rod during the process. This method results in the highest grade of copper content of 99.99%.

TA WIN UPCAST® plant produces 8mm cu-wire rod (oxygen free & high conductivity) by UPCAST®

The Principle of the UPCAST® process is to cast molten copper continuously through a vertical die.

The Lower end of the die reaches into the melt, while the metal in the upper end is solidifying inside the die and the solidified product is pulled upwards through the die to the set of pinch rolls of the withdrawal machine.

The Important properties compared with other copper rods

- Low oxygen level

- Low impurity level

- Immunity to hydrogen embrittlement (excellent weldability, brazability and solderability)

- Good fatigue strength

- Excellent impact strength and flow characteristics

- Good Workability

UPCAST® process is composed of the following:

- Charging Machine

- Melting Furnace

- Laundering System

- Holding/Casting Furnace

- Withdrawal machine / Rod Casting

- Coiling Equipment