Wire Drawing is the process used to reduce the diameter (size) of the rod or wire by repeatedly pulling it through a series of drawing dies. The wire can be annealed to enhance and maximize ductility and conductivity or can be produced in hard drawn condition.

There are many applications for wire drawing, including electrical wiring, cables, tension-loaded structural components, springs, paper clips, spokes for wheels and stringed musical instruments.

TWI has imported the latest models of Drawing Machines and Coating Machines to maintain the competitiveness as well as provide higher quality products to meet the requirements of all customers.

Copper Conductor Bunching and Stranding Process

After the annealing process, the copper wires of different sizes are bunched or stranded together. These wires then pass through nuzzling process to improve the finish of the wires.

There are multiple wires feeding into a bunching machine to be assembled into a bunch or a strand. The phase stranding process consists of assembling some strands or cables for the construction of a multi-conductor cable. Depending on the shape of its cross-section, this process can be called round stranding or sectoral stranding. These 2 processes can be carried out either with flexible or rigid and either with bare or insulated conductors. The shielding process will be used to avoid the electric current which is going through the cable from making noises and interferences.

Generally, the cables which are produced this way will be eventually sheathed. The armouring process offers the cable when installed underground a mechanical protection against strokes, tensions and rodents.

Several single wires or bundles are bunched together. Those single wires do not hold a fixed position inside the strand. Their position relative to one another undergoes a permanent change along the entire length of the bunch.

Electron Beam Irradiation Technology Process

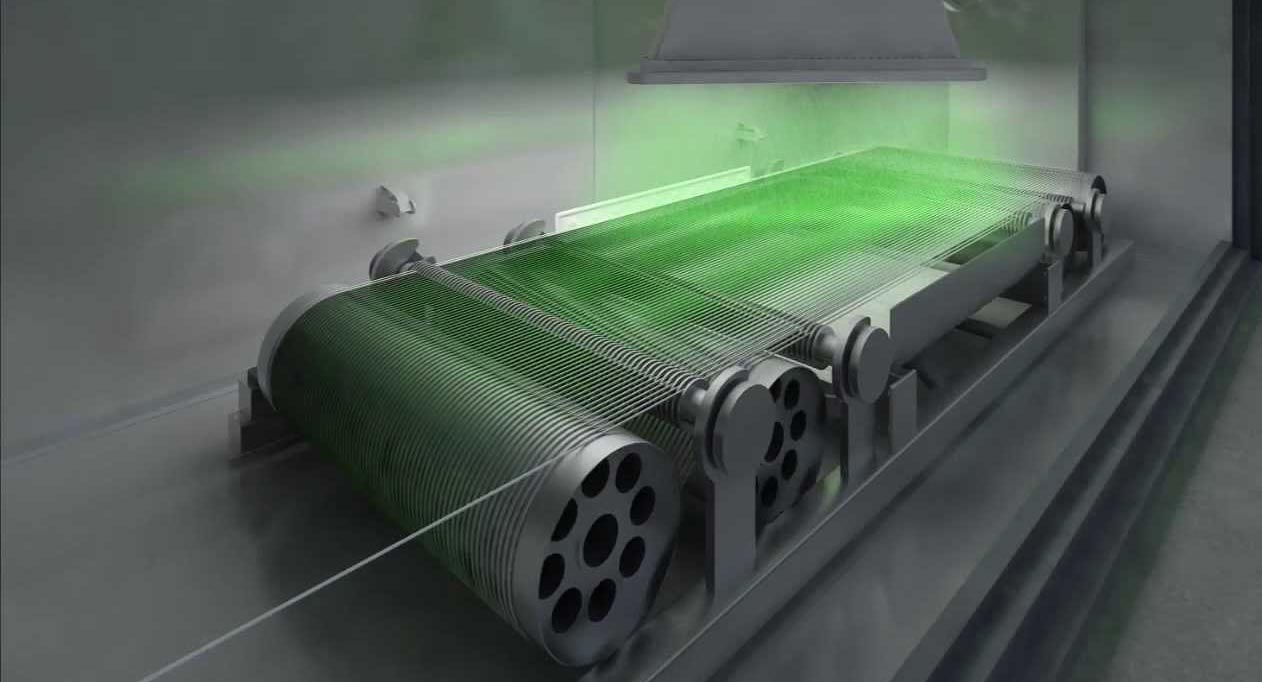

The Electron Beam technology is a leading technology in producing electron beam irradiated wire and cable.

Electron beam processing or electron irradiation is a highly efficient and innovative process involving environmentally friendly – clean and safe – irradiation treatment of polymer-based wire and cable products. It uses high-energy electron-beam accelerator to improve mechanical (wear and tear surface resistance) thermal (temperature, aging and impact resistance) and chemical (stress crack resistance) properties of polymer.

The Technology crosslinks (by modifying the component and jacketing structure of) polymer with high energy electron beam 1.0MeV to 3.0 MeV and thereby increases its melting temperature from typical 110°c to 300°c and lengthens its lifespan from typical few years to more than 25 years. The insulation will not melt and flow should the conductor become heated due to a shorted electrical circuit. Ionized polymer will also be protected during a soldering operation, when a short circuit condition occurs or at high temperatures, as near the engine or exhaust pipe of an automobile. The risk of flame propagation will also be severely reduced should a fire occur in electrical equipment.